Time:2020-06-16 Reading:11240

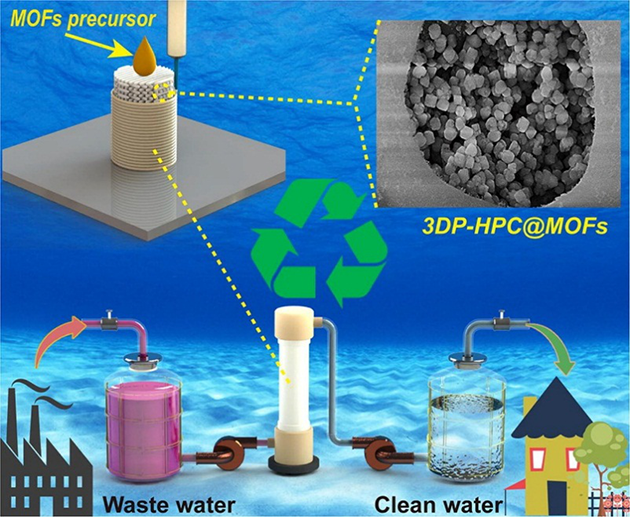

Catalytic degradation is a potent solution for treating wastewater polluted with organic substances. Recently, due to their vast surface area, adjustable pore structure, and abundance of active sites, Metal-organic frameworks (MOFs) have become a new type of catalyst for removing organic pollutants. However, many of the reported MOFs composite materials face challenges in scalability, water stability, and recyclability, hindering their broad and sustainable industrial applications. Therefore, combining MOFs with carrier materials to construct new functionalized MOFs devices can enhance performance and expand their practical applications.

To this end, a team led by researcher Wang Xiaolong from the Lanzhou

Institute of Chemical Physics of the Chinese Academy of Sciences collaborated

with Associate Professor Zhou Lincheng's team from Lanzhou University.

Leveraging the advantages of 3D printing in constructing complex devices and

freedom in design, they developed 3D printed MOFs modified porous ceramic

catalyst materials and devices for catalytic degradation of organic pollutants

in water (Figure 1).

Figure.1 3D printing MOFs-loaded porous ceramics and catalytically degraded organic matter polluted water treatment

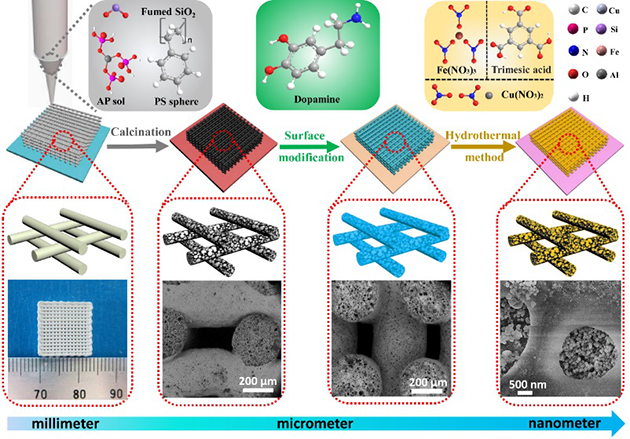

As shown in Figure 2, the researchers developed a 3D-printable ceramic

ink composed of aluminum phosphate sol (AP), hydrophilic gas-phase SiO2, and

polystyrene microspheres (PS). The PS microspheres adjust the porosity of the

3D printed ceramics. Using direct ink writing (DIW) 3D printing technology,

they achieved precision multi-level porous ceramic frameworks, which after

high-temperature calcination, were then modified with polydopamine and treated

with a hydrothermal method to in-situ grow MOFs particles. This resulted in

MOFs modified 3D printed porous ceramics with adjustable structures, high

catalytic activity, long-term stability, and easy device integration.

The resultant MOFs-loaded porous ceramics, with a multi-scale porous

structure encompassing nano, micro, and millimeter scales, exhibited excellent

catalytic performance towards simulated organic pollutants like Methylene blue

(MB), Rhodamine B (Rh B), Malachite green (MG), and Crystal violet (CV). This

was due to their high surface area, favorable permeability, and efficient water

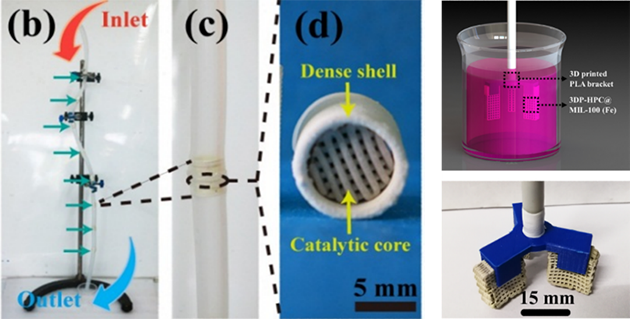

treatment capability. Utilizing the advantages of 3D printing in design and

manufacturing, the researchers optimized the structure and catalytic

performance of the ceramic catalyst material. Additionally, they conveniently

developed various types of catalytic reaction devices using 3D printing

technology, such as the 3D printed catalytic filter and impeller mixer shown in

Figure 3. The resultant devices showed excellent organic dye catalytic

degradation performance and reusability, indicating the potential and

significance of 3D printed MOFs modified porous catalytic materials and devices

in practical wastewater treatment.

Figure.3 3D printing MOFs@ porous ceramic catalytic filter, impeller stirrer and application demonstration

The aforementioned findings were recently published in the international

journal Chemical Engineering Journal (DOI:10.1016/j.cej.2020.125392). The

co-first authors of the paper are Master's student Liu Desheng from Lanzhou

University and Ph.D. student Jiang Pan from the Lanzhou Institute of Chemical

Physics. The corresponding authors are Associate Professor Zhou Lincheng from

Lanzhou University and researcher Wang Xiaolong from the Lanzhou Institute of

Chemical Physics. This research was supported by the National Natural Science

Foundation and the Gansu Provincial Major Special Science and Technology Plan.

This article was sourced from the WeChat public account "catalysis".